EXPERTISE

Oil spill, operational oil leak, illicit discharges, chemicals, debris or objects released or lost at sea, pollution trapped in a wreck … MARINE TECH focuses on accidental marine pollution from diverse origins.

Surveillance and detection

With its experience in the marine environment monitoring, MARINE TECH has a strong expertise in marine pollution detection. To do so, the company implements airborne and maritime means, and dedicated sensors to locate and track pollution.

Engineering and Innovation

MARINE TECH R&D department develops innovative solutions for marine pollution recovery. Among them, NOTIL created to collect floating pollution that can not be recovered by conventional solutions like skimmers.

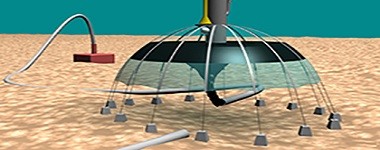

Following the accident of the Deepwater Horizon platform in 2010 in the Gulf of Mexico, our experts have designed and engineered a solution to contain and recover oil and gas leak in very deep water, a patented technology.

Training

To provide optimal customer service, MARINE TECH also offers training, including the implementation of the solutions developed for each specific case.

Our objective: to prevent marine pollution and reduce their impact on the environment.

A NEW SOLUTION: THE NOTIL

DESCRIPTION OF THE PRODUCT

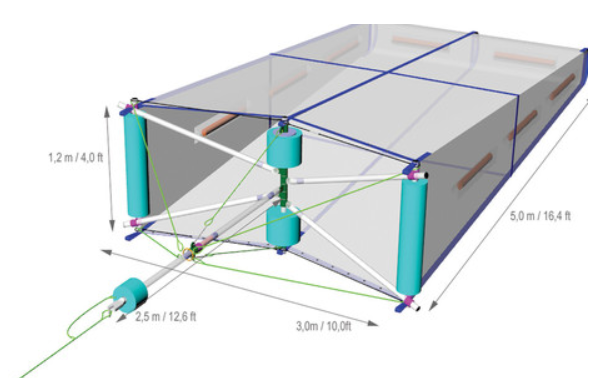

Developed in 2010 following the accident of the Deepwater Horizon platform in the Gulf of Mexico, the NOTIL is a new generation trawler to recover oil spills. Marine Tech manufactures and distributes the NOTIL exclusively.

NOTIL was designed according to precise specifications, including to be usable by many people and from all types of boats (with engines> 50 Hp).

Its size and weight (50 Kg) allow easy transport and deployment: two operators are sufficient to load several NOTIL on a boat and operate them. The implementation time of NOTIL is less than 5 minutes.

In addition, this equipment has been developed to meet primarily the safety of the operators and to avoid contact with the pollutant thanks to its automatic opening and closing system.

NOTIL can be launched right out of packaging without any additional manipulation. Towing by the boat, the drag exerted on the NOTIL structure will deploy it. Once full of oil, the NOTIL is closed thanks to a closing rope sealing the content inside the net.

Depending on the characteristics of vessels mobilized, the net full of pollutant can be loaded onboard the vessel or towed to waste treatment facilities.

Maximum capacity of recovery of each net is 10 m3. Several size of mesh are proposed to match a large range of oil viscosity.

100% recyclable, NOTIL is patented (FR1002892) and several oil spill response team around the world are equipped with NOTIL, including the French Navy.

Download Notil brochure (in English or in Arabic).

NOTIL IN ACTION

SURVEILLANCE AND DETECTION

Better monitor the environment and better detect marine pollution

Thanks to the radar satellite imagery, it is possible to detect offshore marine oil spill before it reach the coast.

In addition, aircraft equipped with special detection sensors (IR,…) are able to identify the pollution.

The company, in partnership with an extensive network of experts, has this expertise to implement aerial survey.

The information collected is the first support to help the authorities to define the response strategies to fight against pollution.

For hazardous areas, MARINE TECH owns a special version of its marine drone RSV equipped with specific sensors for measuring the concentration of polluting substances on site.

PREPAREDNESS

The efficiency of pollution response depends on the level of preparedness of personnel and response means available.

Risks and needs assessment

Because it is essential to identify hazardous activities and sensitive environments to pollution, MARINE TECH performs sensitivity studies and audits of response means in order to assess needs and develop contingency plans in case of risks of marine pollution.

To be equipped, to be trained

To manage marine pollution and protect the coats as best as possible, specific pollution response equipment are required: booms, skimmers, pumps, dispersants, sorbents, etc.

MARINE TECH also offers trainings of personnel in order to prepare them to offshore operations; theoretical and on site trainings.